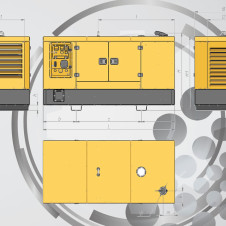

CANOPY

ERGA SOLUTIONS TO ENSURE UNINTERRUPTED POWER SUPPLYPRODUCTION

ERGA Manufacturing plant is equipped with DURMA machines. The DURMA is the biggest European manufacturer of high quality metal processing equipment.

Metal sheets are being cut with computerized plasma cutting machine. This type of equipment is characterized by high precision and rapid cutting speed. DURMA technology allows work in compliance with all environmental regulations and with a high degree of security.

Coating of metal is being done with the use of spray powder on the automatic coating line. High quality of painting computer control system. Possible to paint in any color of RAL.

Use of noise insulation hoods at manufacturing of diesel generators.

Coating of metal produced at the special automatic spray powder coating line. High quality paint provides computer control system. Possible to paint in any color of RAL.

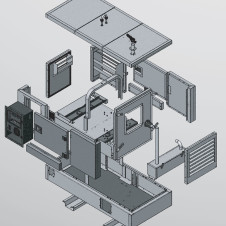

On the assembly line of metal is assembled Canopies for diesel generators. Assembly accuracy is achieved through the use of conductors (rigid metal frames, assembly tables with high precision manufacturing, equipped with terminals, lugs and clamps) on which to create the geometry of each part. Conductor allows assembly with high precision.

Canopies for diesel generators are monitored technical service.

Appointment of anti-noise insulating hoods for diesel power plants.

- Reduces the noise level and vibrations emerging from the equipment

- Protection of sediments

- Manufacturing can be organized in the residential areas and in the close proximity to the consumers

Design Features:

- Thick metal wall guarantees higher rigidity

- Inner lining of fire-retardant insulation material

- Air pockets for noise reducing

- The muffler within the housing

- Fuel tank built according to the standards and with increased capacity of the frame

- Special boxes for diesel generator controller installation

Image gallery